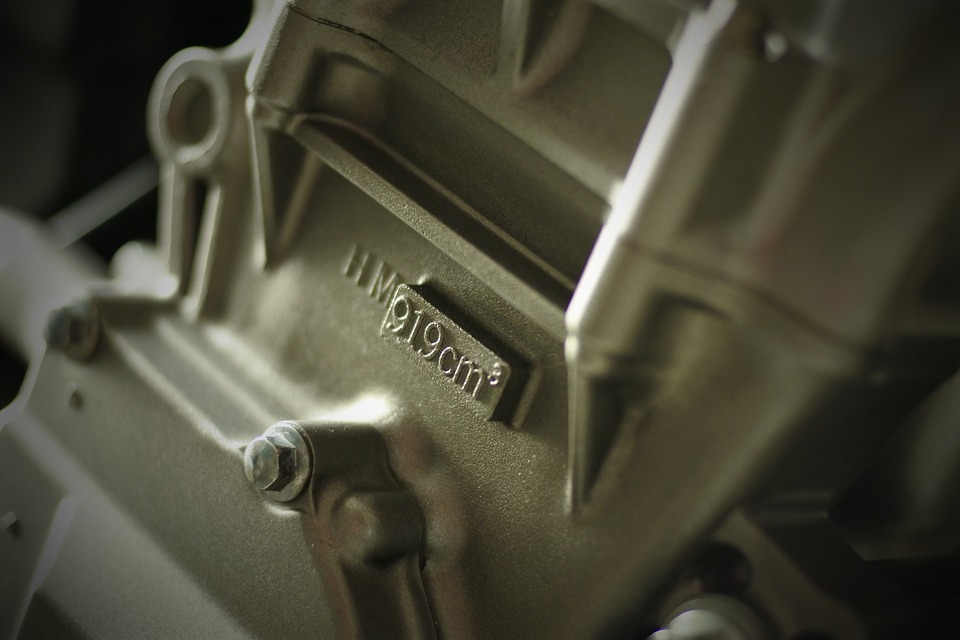

An engine mount is a tool designed to accommodate a car engine to facilitate maintenance or repair work. The engine mount is an essential part for the longevity of your engine. In the event of a defect, it can damage your vehicle’s engine and related equipment or parts. What is the engine mount? And what is it for? Let us look at how it works and how it is used.

Engine Mount: What Is It?

An engine mount is a piece of workshop equipment that is widely used in professional garages. It is also sold commercially to private individuals who carry out extensive work on their vehicles.

Two Functions Of An Engine Mount

During Your Ride:

As its name suggests, the engine mount is used to support the engine. During your ride, it is used to absorb shocks due to vibrations induced by engine operation. Indeed, the engine mount is essentially made of two materials: rubber and metal. The rubber absorbs shocks, and the metal supports the weight of the motor.

During Repair Operations:

Some car maintenance or repair operations cannot be performed when the engine is in place in the car. The engine must, therefore, be removed from the vehicle and placed on a support that will allow it to be easily worked on, or simply stored safely while work is being done on the car.

Caution: do not confuse the engine mount with the tools, such as a lifting crane, that extract the engine from the car. An engine mount is not used to remove an engine from a vehicle. It is instead used to support the engine

How Does It Work?

There are several types of engine mounts. But the vast majority of engine mounts are made up of 3 parts:

i) a base with wheels to easily move the motor support;

ii) a vertical arm that raises the motor sufficiently so that it is at a practical height to work on it;

iii) a plate that can be rotated on the vertical arm and forms the interface with the motor.

Good to know: the plate swivels on the arm, it is possible to turn the motor once it is fixed on the support, and to easily access its lower part if necessary.

Placing The Motor On An Engine Mount

Whatever its type, an engine is always a heavy object. It is, therefore, necessary to be careful and follow the correct order of assembly to place a motor safely on the bracket.

Most engine mounts are designed to be connected to the engine via the anchors initially designed for the gearbox. It is, therefore, also necessary to remove the gearbox and clutch before the engine can be fixed to the bracket.

The motor should be attached to the bracket (e. g. the engine is suspended from a lifting crane) in this way:

i) position the bracket plate alone on the motor, using the anchor points provided for the gearbox;

ii) using a torque wrench, tighten the connecting screws according to the torque specified in the operating instructions, or according to the diameter of the screw (consult a professional if necessary). It is an important safety step, as the engine is a critical and massive part that must be secured;

iii) place the motor and plate assembly in the axis of the motor support;

iv) rotate the motor so that you can work on the side you need to;

v) block the rotation of the engine and the plate using the mechanism provided for this purpose (clamping screws, pins, etc.).

Choosing An Engine Mount

Among all the supports available in the market, you must choose mainly according to 2 criteria:

i) the engine of your car;

ii) and the price of the engine mount.

For Which Engine?

The majority of motor mounts are universal and have an adjustable plate, to securely fix a motor.

However, care must be taken to ensure that the maximum load allowed by the engine mount is not exceeded. There are significant weight differences between a small city engine and a gigantic engine of a 4×4 or a top-of-the-range sedan.

Good to know: the weight of the motor requires much attention when choosing a lifting crane.

At What Price?

Engine mounts are simple design objects, which do not contain much technology (it is generally an assembly of welded steel tubes).

Note: their strength is essential for the safety of the person using them, and they are not a widely popular product.

The prices are therefore all within the same range, between $55 and $165.

Prices vary mainly with the maximum load that the support can carry. The first range of prices generally concerns engine mounts that can accept a load of 400 kg, which mainly involves a vast majority of car engines.

Hope the above helps you out with your engine.