Contents

– Clutch pedal: characteristics and operation

– Clutch pedal: maintenance

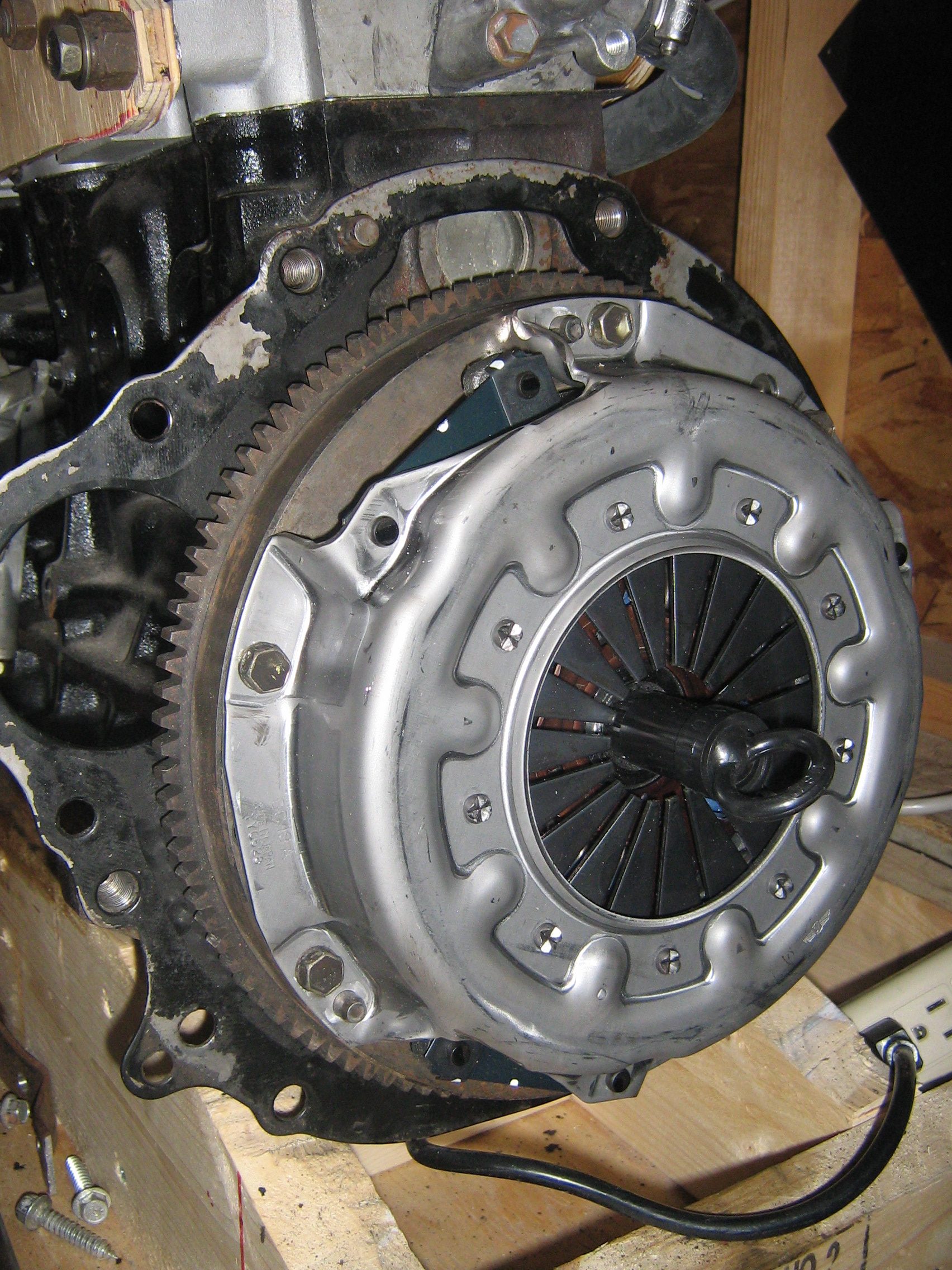

On vehicles with a mechanical gearbox, the clutch allows the power supplied by the engine to be relayed to the wheels. The clutch is controlled by a pedal. The clutch pedal activates two types of controls: cable control and hydraulic control.

Clutch pedal: characteristics and operation

The traditional car pedal has three pedals. The one that controls the clutch system is installed on the left. Pressing the pedal with the left foot disengages the clutch, and releasing it engages the clutch.

Cable clutch

The pedal activates a cable control with a cable clutch, which connects the pedal to the clutch release bearing. When the pedal is depressed, it pulls on the cable, causing the clutch to disengage.

Hydraulic clutch

When the car is equipped with hydraulic clutch control, the pedal pushes a piston in the clutch sender, pushing hydraulic fluid to the clutch receiver. This fluid, in turn, pushes another piston which causes the clutch to disengage. Once the gearbox ratio has been changed using the gearbox control lever, simply release the pedal to engage the engine to the transmission.

Good to know: the hydraulic clutch system uses the same fluid as the brake system. Depending on the make and model of the car, the fluid is stored either inside a jar dedicated to the use of the clutch or in the same jar like the one activating the brake system.

Clutch pedal: maintenance

Freewheel adjustment

Although many cars today have an automatic clutch freewheel adjustment device, monitoring and possibly adjusting the freewheel is necessary. The clearance is the adjustment that prevents the clutch release bearing from wearing out.

– If the clearance is insufficient, the release bearing will constantly push the mechanism, accelerating its wear and causing the clutch to slip at each gear change. This can be felt at the steering wheel through the slippage in the transmission, which leads to a loss of acceleration.

On the other hand, if the clearance is excessive, the clutch disc will have difficulty moving from its position to allow proper shifting, resulting in difficult shifting and cracking.

Adjusting the clearance of a cable clutch

When your car is equipped with a cable clutch control, here is the procedure to follow to adjust the clearance:

– Take the dimension at the pedal or fork.

– Loosen the locknut on the cable sheath on the bracket attached to the transmission.

– Turn the toothed sector while holding the sheath stationary until the pedal clearance is correct.

Press the pedal down a few times, recheck the setting, and then tighten the locknut.

Good to know: don’t forget to lubricate the exposed part of the sheath with a bit of grease.

Adjusting a Hydraulic Clutch Control’s Guard

Most of the time, the clearance is adjusted automatically. However, there is a possibility of presetting it if the clutch slips or the gears crack.

A threaded rod comes out of the hydraulic control’s slave cylinder. The end of this rod is screwed into a piece attached to the end of the fork, which is locked by a locknut.

– Loosen the locknut.

– Turn the rod on itself with pliers.

– To decrease the clearance, unscrew the rod in the fork; to increase the clearance, screw the rod in.

– Adjustment is made by measuring the dimension in the same way as the mechanical control. You must respect the manufacturer’s adjustment instructions, which vary from car to car.

– When the adjustment is made, lock the locknut while holding the rod to prevent it from turning.

Now you know how to maintain a clutch pedal. If DIY is not your cup of tea, you’ll have to look for a professional mechanic in your region. Remember to share your experience in the comments below.