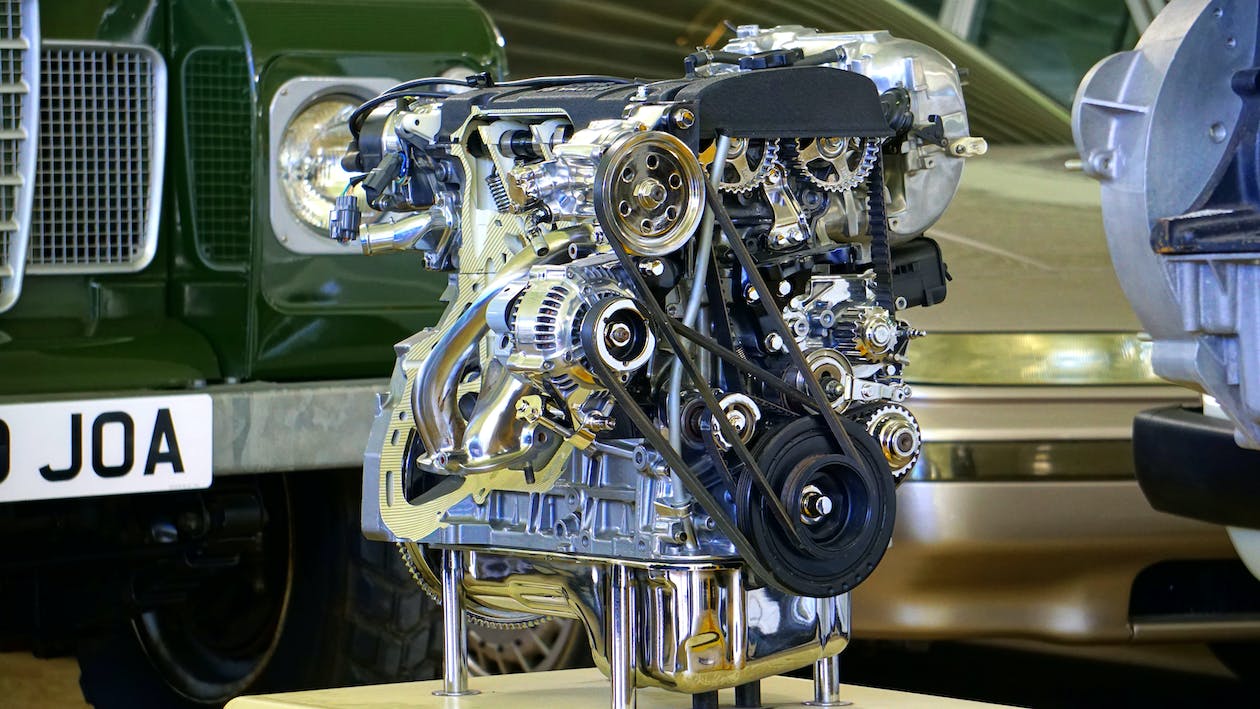

The alternator belt, more correctly called the “accessory belt”, transmits the engine’s mechanical energy to the various auxiliaries such as the alternator, the water pump (which can also be driven by the timing belt), the power steering pump and the air conditioning compressor.

Composition of the alternator belt

Once made of leather, then rubber, the accessory belt is now a high-tech product of polyamide materials reinforced with a fibrous structure. Its specifications include the following requirements

– be flexible and fit the windings on the pulleys and rollers;

– be resistant to tensile stress and wear;

– withstand the high temperatures generated by the motor and the mechanical friction on the pulleys;

– resist various chemical and foreign body aggressions (oil, hydrocarbons, dust, gravel, etc.).

Types of alternator belts

V-belt

As its name indicates, its section is trapezoidal.

This is an old-generation belt, which is hardly used on modern vehicles.

Grooved belt

This is the current belt. It is much more efficient in driving all energy-consuming ancillary systems, as a single belt can now do this work. Hence the simplicity of assembly saves weight and space.

It is flat and has teeth (3 to 6) in its lower part in the longitudinal direction (this imprint is negative on each pulley).

Alternator belt: tensioning systems

Belt tensioning is a crucial phase in belt replacement and can lead to premature belt failure if it is not done properly.

There are several types of tensioning systems:

– Tensioning by manual pulley-tensioner: it is the operator who must adjust the tension by adjusting the tensioning roller. For the do-it-yourselfer (and even for the professional), this is a high-risk operation, and tensioning by trial and error should be avoided. It is, therefore, necessary to use a measuring device, the “tensiometer”, which will give you, depending on the model, a value in hertz (frequency) or unit of tension force (N) to be compared with the manufacturer’s nominal value given in the technical review corresponding to your vehicle.

– Automatic tensioning: here, no problem with tension value; this one is established by the tensioning roller, which, thanks to an internal tared spring, will adjust the good tension.

Caution: the difficulty lies in the installation of the belt, which is very difficult to achieve by a single person. Get help to slacken the automatic roller (often with the help of a flat wrench), a delicate operation because of the effort required and the limited space to operate. It is important to use the same size belt as the original one for optimal tension.

Note: Some manufacturers (Renault, for example) have opted for a belt without tension adjustment and a tensioning roller on some of their models. For this type of assembly, it is important to have the manufacturer’s tool (or to make one for the most do-it-yourselfers). Otherwise, the belt may be damaged.

Symptoms:

– Visual appearance: if it shows signs of cracks on its back or in the serrated teeth, it is urgent to replace it.

– Running noises at start-up: high-pitched squealing or metallic noises may indicate a slack belt or a damper pulley in poor condition. In this case, adjust or replace the defective components.

– Is it a damper pulley issue? The motor pulley consists of a hub separated from the pulley by a rubber strip that filters vibrations and jolts (this rubber part can break down).

– A slight knocking noise often accompanies the vibration of the belt. If the vehicle is equipped with one, it is often the defective dynamic tensioner roller; replace it with its belt as a matter of urgency.

Advice: in some cases, it may be more appropriate to have your vehicle diagnosed and replaced by a specialist, depending on the degree of accessibility and the specific nature of your car (e.g., Start & Stop equipment with starter-alternator).

Alternator belt: practical advice

Where to buy it?

There are several possibilities:

– from a dealer,

– at an automotive supplier,

– On the Internet: provided that you order branded belts (original or well-known brands: GATES, HUTCHINSON, etc.) and the recommended size.

The cost will vary according to the belt size and the supplier, from $10 to $80.

Replacement frequency

Refer to the manufacturer’s recommendations: every 2 or 4 years, at the same time as the timing belt or in the event of symptoms of aging

It is essential to check the accessory belt periodically. Indeed, a defective belt disintegrates, and the pieces can pass into the timing belt with the risk of the destruction of this one and the engine.

1 comment

[…] When Should I Change the Alternator Belt; […]