Summary

– Gearbox: what is it used for?

– Operation of a manual gearbox

The gearbox is an element of a vehicle’s transmission, allowing more flexibility in transforming the engine’s movement. This post provides you essential information on how a gearbox works, so next time the mechanic talks about manual transmission, you’ll know what he is talking about.

Gearbox: what is it used for?

A gasoline or diesel engine works on the same principle and, with a mixture of air and fuel, creates a rotary motion. This torque force is recovered and transmitted to the wheels through a transmission.

An idling engine runs at around 800 rpm and typically rises to 6,500 rpm (5,500 for a diesel):

– At this speed – with wheels whose average perimeter is around 1.65 m – the vehicle would travel at 80 km/h at idle and over 600 km/h with a full load.

– This is, of course, impossible for several reasons, including the power required for such a movement.

Therefore, it is necessary to create a device that allows the engine speed to be reduced to give the vehicle a reasonable speed range.

In addition to speed, it is also a question of power. A considerable amount of energy is required to bring a vehicle out of a state of equilibrium, i.e., from 0 to 1 km/h. Therefore, it is necessary to provide several levels of gear ratios that, as a bonus, further increase the power transmitted as they are reduced.

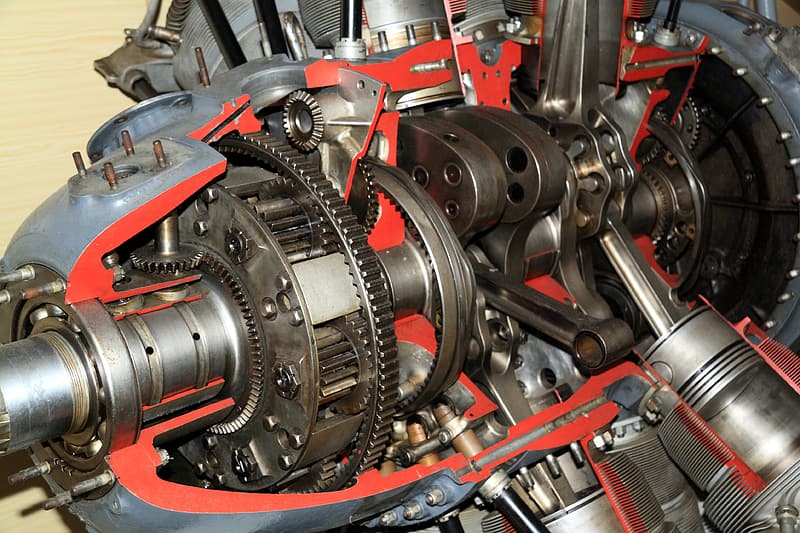

This is how the gearbox was born since it represents a compartment in which several gears have been assembled, each representing a range of reduction of engine rotation.

Operation of a manual gearbox

Leverage operation

A reduction gear works straightforwardly: small pinion on the motor side and large pinion on the wheel side to reduce rotation speed. The opposite happens for a large pinion on the motor side and a small pinion on the wheel side. It’s the same principle as the transmission of a bike with the gear change, all proportions kept.

In the case of standard transmission, let’s count 5 gears; the reduction gears are placed on two shafts: a shaft for the driving gears (by the motor, primary axis), a shaft for the driven gears (towards the wheels, secondary axis) :

– They are all of the different sizes and together represent gear ratios defined by engineers to allow the vehicle to operate in the best range.

The primary and secondary axles are parallel, and the shift lever’s action allows them to slide to engage the target gear and release the previous gear.

– The clutch is located upstream of the drive sprocket and enables the transmission to be relieved of any engine drive during shifting.

The terms used to refer to the gear ratio level :

– A “short” gear or gear ratio means that the vehicle will go slowly but will have a high gear ratio, meaning excellent transmission of power to the wheels but low top speed.

– Conversely, a “long” gear ratio or transmission, gives the vehicle more speed but requires more power to be driven.

The gearbox is then defined, taking into account functional and usage parameters:

– A first gear is required to allow the vehicle to move forward from a complete stop without the engine shutting off by power default.

– Subsequent gears must be sufficiently stepped to allow a smooth and comfortable gear change (there must not be a large jump in the gear ratio between two gears).

– The different gears must provide a range of power transmission sufficient for all situations in which the vehicle may find itself (i.e., depending on its use).

– A reverse gear is required to allow the car to be reversed.

– A neutral gear must be accessible to disengage the transmission from any mechanical drive with the engine or wheels.

– The final gear ratio must enable the vehicle to reach its maximum speed at the end of the engine speed range or allow the car to be at its minimum fuel consumption speed at the usual legal speeds in the country of sale.

Note: these conditions allow the vehicle to be comfortable to drive and economical to use.

In addition to this assembly, there are thrust and synchronization mechanisms to ensure that the two axles’ pinions engage correctly with each gear change (and avoid the unpleasant cracking sound of a bad shift occurring when two pinions are poorly synchronized).

Finally, the gearbox is oil-lubricated to allow for better mechanical transmission of forces.

Stay posted for new posts coming up on:

– Example to better understand how the manual gearbox works

– Maintenance and wear of a manual gearbox

– Manual gearbox: technological developments

3 comments

[…] How Does a Manual Transmission Work […]

[…] The manual transmission is a part of the transmission of a vehicle allowing more flexibility in the transformation of the […]

[…] ◦ Manual gearboxes: the driver must select the transmission ratio to engage himself. He must also manually disengage a clutch to allow the gear to shift. […]