Summary

– Lightened flywheel: definition of power

– Lightened flywheel: why?

– Lightened flywheel: advantages and disadvantages

– Lightweight flywheel: maintenance and cost

How to boost the power of a vehicle? This is possible thanks to engine preparation, carried out by engine technicians, often intimately linked to the competition.

One of the most critical factors in this preparation is the lightening of the engine flywheel; indeed, a lightened flywheel improves power exploitation. Let’s see why and how.

Lightened flywheel: definition of power

The power of an engine is expressed by the formula: P = W/T.

Note: W is the combustion force’s work in joules; T is the time in seconds.

However, this unfriendly formula is exact: it means that power is a function of time and that the more combustion forces are applied in a short time, the greater the power.

Concretely, the actions to be taken to improve power are :

– Reduction of the crank arm of the crankshaft, which leads to a reduction in the length of the piston stroke: if the piston takes less time to move up and down, the number of combustions will be increased in a given time ;

– the increase in the piston surface area which, in interaction with the previous parameter, illustrates a “super square” engine configuration;

– the lightening of moving parts (connecting rods, pistons, valves, etc.);

– the lightening of the engine flywheel.

Note: “super square” means a bore value (cylinder diameter) greater than the piston stroke’s value.

Lighter flywheel: why?

Flywheel function

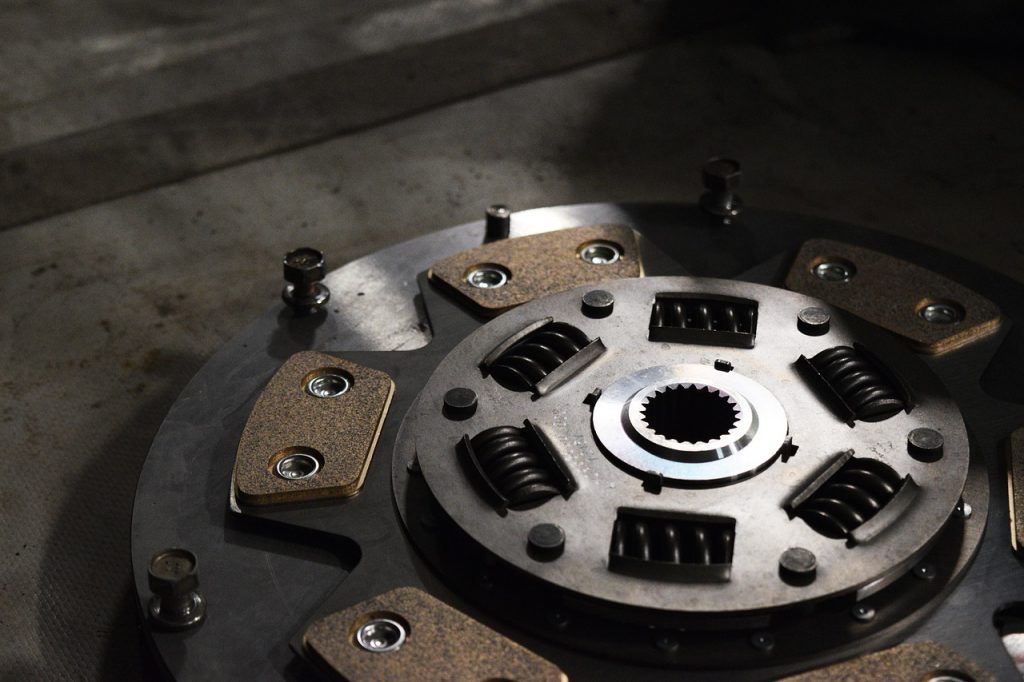

The engine flywheel is a circular piece of 25 to 30 cm in diameter for a passenger car, made of cast iron, therefore hefty, fixed at the end of the crankshaft.

Its role is double. Not only does it support the clutch mechanism and acts as a support face for the clutch disc, thus ensuring the transmission of the engine movement, but it also has an essential role as a flywheel. Its mass absorbs the jerky energy of the cylinders’ combustion to restore it regularly and thus limit the variations in movement.

Therefore, it allows the engine to be balanced, avoids destructive vibrations to the mechanics, and generates driving discomfort.

The interest of lightening the engine flywheel

Initially, the engine flywheel takes a lot of power because its inertia slows down the rises in rpm; in this acceleration phase, if the rotation speed does not increase fast enough, the combustions are more spaced out, so the engine’s power at low rpm suffers.

The solution is, therefore, to lighten the engine flywheel.

Lightened flywheel: advantages and disadvantages

The benefits of lightening the flywheel are as follows:

– Faster rises in speed;

– faster power delivery;

– increased performance.

But it also has disadvantages:

– loss of engine torque efficiency;

– uneven operation and increased vibration;

– uneven idling;

– increased fuel consumption (more combustion).

Lighter flywheel: maintenance and cost

To lighten the engine flywheel, you can choose between two solutions:

– Modification of the original flywheel: the operation consists of judiciously removing material from the flywheel to reduce its weight.

– Replacing the flywheel: This is the simplest solution, as many repair shops offer modified flywheels or flywheels made of lighter metal (e.g., aluminum).

The cost and suppliers vary according to the chosen solution:

– Lightening of the flywheel can be done by hand with a metal lathe and milling for material removal. This solution is the most economical (average price: $150) but may involve errors due to the fitter’s lack of knowledge of the specific engine techniques.

– The supply of a lightened flywheel ($250 to $500) has the advantage of being carried out by automotive preparation workshops for tuning or competition (Oreca-Store, Street MotorSport, BPS Racing…), and of being able to ensure, consequently, real performances.

1 comment

[…] the fork in parallel, causing the freewheel and its pinion to move—the pinion meshes with the flywheel‘s teeth attached to the crankshaft and drives the combustion […]