Contents

– Different types of injection pumps

– Injection pump: possible failures

– Price of an injection pump

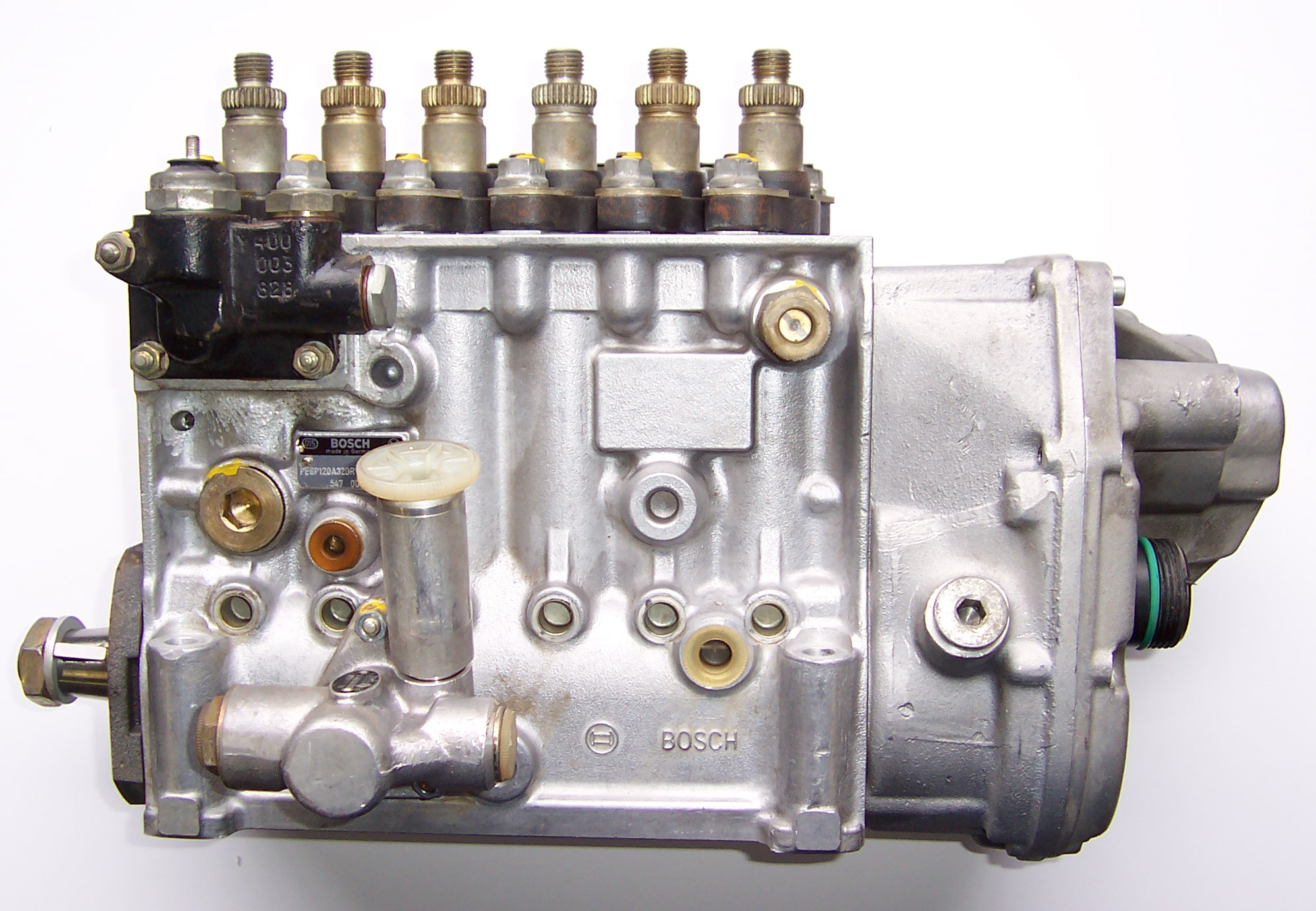

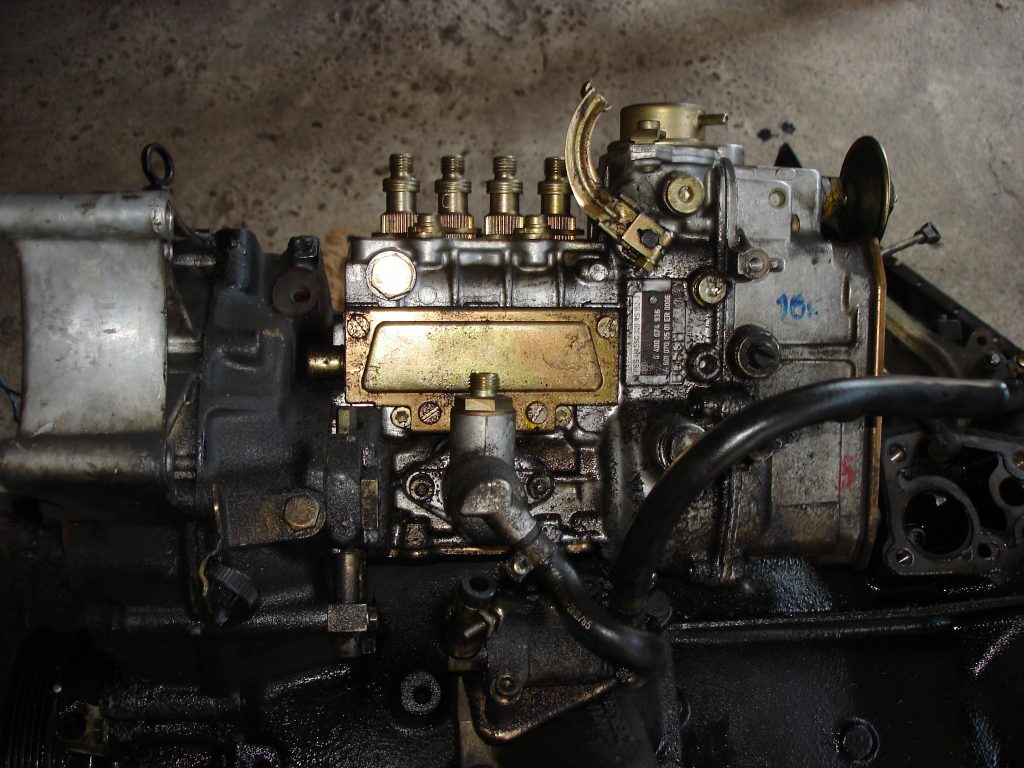

The injection pump is a mechanical device that creates a constant pressure to distribute fuel to the engine’s different injectors. Rudolf Diesel invented the first injection pump in 1895; it was a compressed air pump that did not allow for high engine revolutions.

In 1925, Robert Bosch invented the first injection pump that would allow higher engine rotations. This post will tell you just what you should know about that essential component of your vehicle.

Different types of injection pumps

There are several types of injection pumps for diesel and gasoline.

For gasoline vehicles, there are mainly three types: single-point injection, multi-point injection, and direct injection.

For diesel vehicles, there are mainly three types as well:

– The in-line or rotary injection pump: its pressure is between 100 and 250 bars.

– The common rail high-pressure injection pump: its pressure is between 1,600 and 2,000 bars. The injectors are controlled electrically by a computer.

– The high-pressure injection pump with pump injectors: its pressure is between 1,600 and 2,000 bars. The pump injectors are controlled electrically by an ECU.

Since the year 2000, most vehicles are equipped with high-pressure pumps. High-pressure pumps coupled with electrically controlled injectors allow more homogeneous atomization in the engine.

The better fuel metering limits unburnt fuel in the exhaust. This results in less pollution and fuel consumption for the same power.

Injection pump: possible failures

The fuel is pumped and pressurized by the injection pump. It is then distributed to the different injectors or common rail of the engine according to a defined cycle with an optimum dosage according to the engine’s different speeds and loads.

The most common failures are, for example:

– a drop in pressure of the injection pump;

– a leak from the injection pump;

– a problem with the various solenoid valves of the injection pump;

– water in the fuel;

– clogged fuel filter;

– seizure of the injection pump;

– premature aging of certain injection pump components (presence of filings in the fuel filter).

The following warning signs can help you recognize a breakdown:

– loss of power and efficiency of the vehicle

– difficult or impossible starting;

– presence of jerks during acceleration;

– engine stalls or does not stop when the ignition is turned off;

– fuel odor;

– smoke from the exhaust;

– engine management light is on.

Good to know: To keep the fuel injection pump and injectors in good condition, have the fuel filter replaced regularly. Do not leave a vehicle that is not running with a nearly empty tank. This is because the air in the tank forms water condensation.

Today’s fuel injection pumps do not tolerate impurities or water in the fuel system. A regular injection system cleaner can limit the premature degradation of the injection pump and injectors.

Price of a fuel injection pump

An injection pump price varies from approximately $1,000 to $3,000, depending on the vehicle’s make. Replacement times can vary according to the breakdowns observed.

Indeed, on specific breakdowns, the manufacturers’ recommendations require replacing the injection pump, replacing all the fuel pipes, the tank, and the injectors.

You can read further below:

– Do you need to change your timing belt?

– Cars and Vehicles: What is Direct Injection System

– What Causes Poor Fuel Economy?

– 4 Essential Steps to Changing Your Fuel Filter

– How to Avoid Fuel Injector Problems

Remember to share this post and leave your comments below.