Summary

– What is the purpose of a power steering system?

– The different types of power steering, their advantages, and disadvantages

All cars today have power steering. These systems have become indispensable for the comfort and safety of driving. Comparison of functions, advantages, disadvantages, and maintenance: we tell you everything about power steering in this post!

What is the purpose of a power steering system?

The power steering system fulfills three essential functions:

– The relief function. Power steering allows a smaller internal rack and pinion gear ratio and a smaller steering wheel diameter, and less space requirement. It is more direct, reducing the necessary number of steering wheel turns.

– The comfort function. The system reduces the effort required to turn the wheels during low-speed maneuvers.

– The safety function. Due to its adaptability to the driving conditions, the assistance will be maximum at low speed and reduced at high speed to avoid untimely deviations in the trajectory.

Good to know: the various power steering systems must be mounted in parallel with the mechanical steering system, with the driver having to maintain control of the vehicle in the event of a deficiency in the assistance device.

The different types of power steering systems, their advantages, and disadvantages

In automobiles, there are 3 types of power steering operation.

Hydraulic power steering

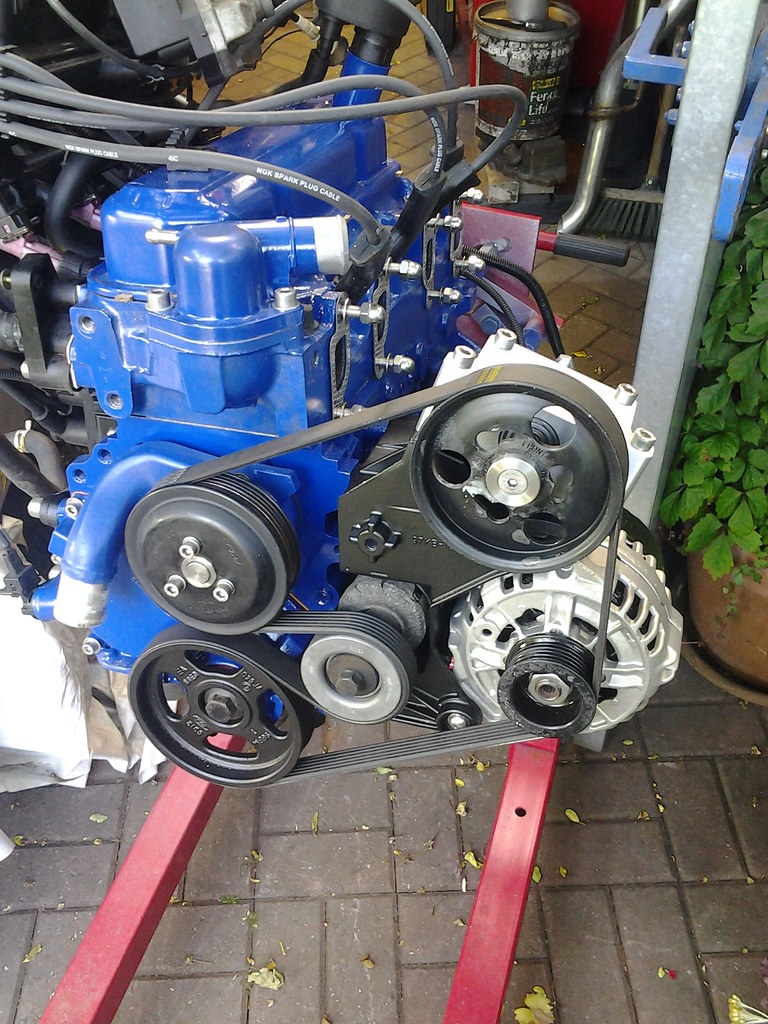

The activation of the system is caused by the flywheel’s rotation, which controls a hydraulic spool. This allows the pressurization of a cylinder placed on the steering bar or rack, accompanying the driver’s effort. Let us see in detail its various components:

– The steering pump: It is a hydraulic vane pump, driven by the engine’s accessory belt, which generates the hydraulic pressure of a fluid, the steering oil, generally the same as that of automatic transmissions. The maximum pressure is 85 to 130 bars, depending on the model, with a pressure limiter (internal or external to the pump) to control it.

– The cylinder: Mounted on the rack, it is a double-acting cylinder (which can receive pressure in extension and in the opposite direction).

– The distributor box: This is a hydraulic spool, integrated into the steering box on the rack:

◦ steering wheel in the middle: the cylinder is not powered;

◦ right-hand steering wheel: one side of the cylinder is powered, allowing right-hand steering assistance;

◦ left steering wheel: The actuator’s opposite side is powered, causing the steering bar to be pushed to the left.

Strong points of the hydraulic power steering:

– Proven system with a known and straightforward fault diagnosis (hydraulic leaks, faulty steering pump…);

– no or very few electrical components.

Weaknesses of hydraulic power steering:

– more constraining maintenance by the lack of accessibility and the multiplication of the components;

– higher maintenance cost;

– continuous operation (additional fuel consumption).

Electro-hydraulic power steering

The hydraulic pump is replaced by an independent electric motor generating the hydraulic pressure. This assembly allows the pressure to be easily modulated according to various parameters (force exerted, steering angle, vehicle speed, etc.) with an ECU.

Strong points of the electro-hydraulic power steering:

– hydraulic pressure independent of engine speed and electric controls more easily modulated according to operating needs (pressure is only generated when necessary, thus limiting fuel consumption);

– Reduced maintenance operations (electric pump assembly placed in an accessible location);

– the limited risk of hydraulic leaks or seepage (absence of the hydraulic pump and long supply and return lines).

The weakness of the electro-hydraulic power steering:

Although the mechanism is simplified, there is still a hydraulic circuit with a cylinder, which is a breakdown source. This is the main disadvantage of the system.

Electric power steering

In this configuration, the hydraulic circuit is suppressed. The driver’s effort on the steering wheel is transformed into an electrical signal by a torque sensor on the steering computer. This then powers an electric motor, integrated with the steering column or rack and pinion, which accompanies the driver’s movement.

Highlights of electric power steering

(in addition to all the advantages of electro-hydraulic steering):

– space-saving system;

– no hydraulic circuit;

– adaptable on conventional racks (no oversizing);

– low-cost system (adapted to the equipment of low-end cars);

– lighter maintenance.

The weak point of the electric power steering:

The engine’s electrical consumption (60 amps) prevents the system from being put into service under 300 rpm. Simultaneously, the alternator can deliver sufficient power (this is why the presence of electric steering is recognizable by the resistance to the rotation of the steering wheel when starting).

Note: most of the time, hydraulic power assistance, although its components are more detailed, requires much more workforce to repair maintenance. On the other hand, preventative maintenance is limited to the replacement of the steering oil (every 3 to 5 years).

1 comment

[…] How Does a Power Steering Work […]